Excellence forging quality model

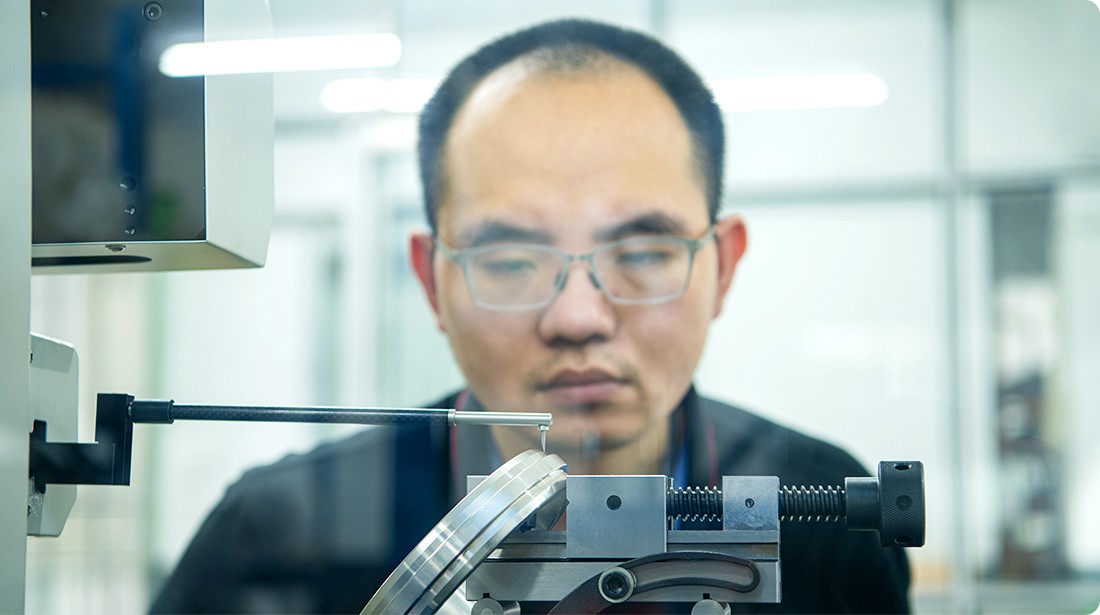

Equipped with modern detection and material test equipment: direct reading spectrum analyzer

Metallographic analyzer, mechanical property test, low temperature impact test, MT, PT

UT, RT and other perfect testing equipment,

Analysis and detection shall be carried out by full-time inspectors,

To ensure the customer's requirements for casting quality.

Whether it’s outsourcing parts,

The parts are still self-manufactured products,

All follow Zhenghai’s unified quality control process standard system,

So as to ensure that the product performance and quality are foolproof,

Let customers worry-free,

Materials for all products

Production, processing, and testing are all traceable,

Not realized

High-tech crystalline products benefit from the

individual and diversified needs of customers

more from the professional laboratory

Here, each product is subject to more than 20 trials and tests

so as to obtain accurate results

Various experimental data greatly improve the reliability

and stability of our products to ensure that

our products meet the highest quality requirements